HEIDENHAIN automation partners:

Competent advisory support for a high security of investment

HEIDENHAIN is firmly anchored within the machine tool industry as an innovative partner with a strong tradition. Our automation partner program helps our customers deeply integrate their controls into an automated production environment. The HEIDENHAIN automation partners include software providers, automation system providers, and turnkey providers. Together, we tailor customers’ projects to their unique circumstances, implementing their projects within the shortest possible time for higher productivity and greater process efficiency in a digital production environment.

The software solutions for the Digital Shop Floor, the Connected Machining package of functions for HEIDENHAIN controls, and our services for digitalizing your processes support you in implementing uniformly digital job management in a networked production environment, including vertical integration with enterprise resource planning systems. Workpieces and tools are always available at the machine when needed, ensuring that all processes run smoothly and without interruption. This brings high productivity to your automated production environment, letting you leverage the full benefits of a digital shop floor.

To submit a project query, you can contact the following automation partners directly:

Turnkey suppliers

Cellro B.V.

Automation example

| Project | Automation of a GF Mikron HSM 600 machining center with a HEIDENHAIN iTNC 530 control |

| Project start | January 2017 |

| Project end | August 2017 |

| Application | Cellro Compact 1500 |

| City, country | 6336 Langkampfen, Austria |

| Industry | Supplier for metal removal machining |

| Products deployed |

|

| At a glance | Various types of products were to be manufactured in the machining center. These products were to be automatically clamped onto one or more pallets and completely machined. The customer desired an automation solution in combination with the machine from a single provider. This was possible through Cellro and GF Machining Solutions. |

| Benefits for customer | Greater spindle efficiency on the machine and higher production capacity. It was possible to manufacture in a single shift, rather than two, as well as over the weekend, which was the main requirement. |

| Contact person | Cellro: Michiel van Buul |

| Contact person | sales@cellro.com https://cellro.com/de |

EROWA AG/CERTA Systems GmbH

EROWA is known for its workholding systems and advisory services in process automation. The company’s “Flexible Manufacturing Concept” forms the basis of its state-of-the art automation solutions for small-batch and single-part production. CERTA Systems GmbH provides the necessary software and process advising. The process control system from CERTA can be integrated into all common applications from the CAD/CAM and ERP/PPS worlds and automates workflows involving machine tools, measuring machines, robots, and handling equipment in a production setting.

Automation example

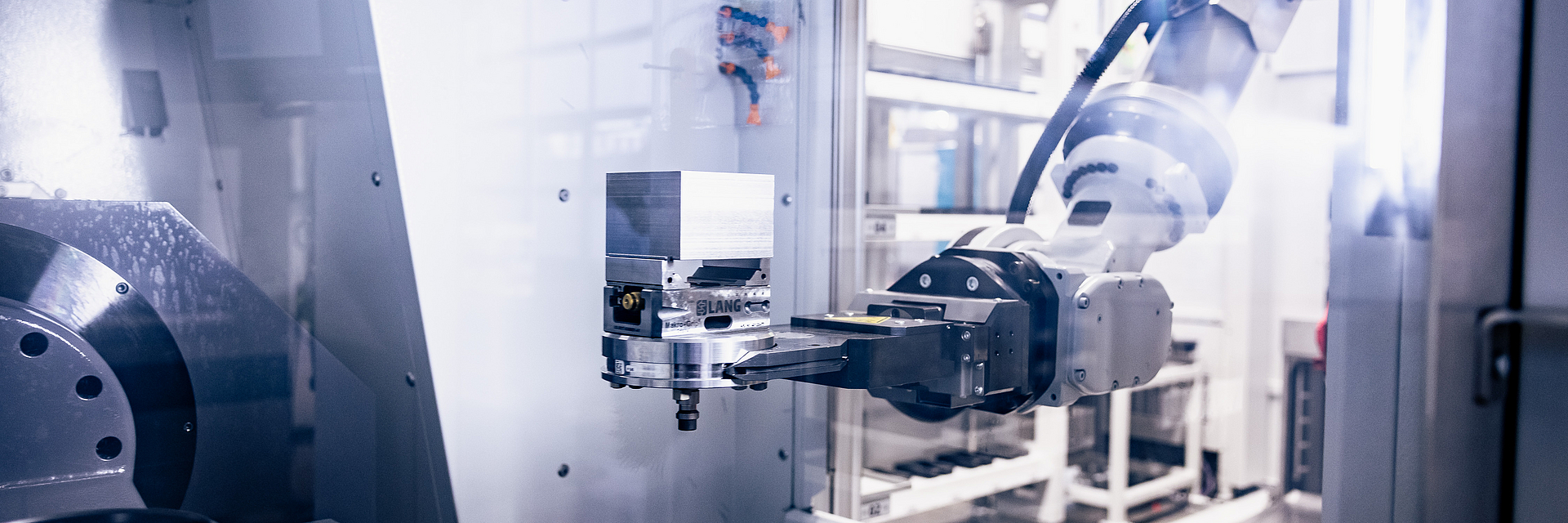

| Project | Automation of a Fehlmann 5-axis milling center with an EROWA Robot Dynamic 150 Linear |

| Project start | April 2017 |

| Project end | August 2017 |

| Application | Production of parts ranging from delicate watch parts to high-quality aerospace components |

| Company | Helfenstein Mechanik AG |

| City, country | 6055 Alpnach / Schweiz |

| Industry | Aerospace, medical technology, gas detection technology, watch industry, machine-building industry |

| Products deployed | Machine

Automation

Process control system

|

| At a glance | This flexible, lean, and extremely user-friendly automation solution enhances the machine, making it a highly productive machining cell with “Made in Switzerland” quality. |

| Benefits for customer |

|

| Contact | EROWA AG: Alois Bättig |

Fastems Systems GmbH

Fastems is a producer of factory automation systems, providing flexible production systems, robot-supported automation solutions, production control software, portal systems, and interlinked systems. The company's RoboFMS ONE pallet automation system, for example, combines the advantages of an industrial robot with those of a flexible production system.

Automation example

| Project | Automation solution for two machining centers for parts production starting with lot size one |

| Project end | 2017 |

| Application | Fastems FastWizard |

| Company | Trimatec |

| City, country | 48356 Nordwalde, Germany |

| Industry | System provider of mechanical milling technology for lot size one and small series of high-quality, high-accuracy workpieces and components |

| Products deployed |

|

| At a glance |

|

| Benefits for customer |

|

| Project link | Report from Klartext 68 |

PROMOT Automation GmbH

PROMOT Automation was founded in the town of Roitham am Traunfall in Upper Austria in 1980. The company specializes in machine tool automation, with a focus on users who machine metals. The versatile module system from PROMOT enables adaptable, fully automated workpiece, pallet and tool handling with the aim of reducing production cost per part.

Automation example

| Project | Automation of machining centers and lathes for small-batch production, including lot size 1 |

| Project start | 2013, PROMOT delivered seven automation solutions |

| Project end | 2020 |

| Company | Weber Maschinenbau GmbH |

| Application |

|

| City, country | Hesse, North Rhine-Westphalia and Mecklenburg-Vorpommern, Germany |

| Industry | Machines for the food-processing industry |

| Products deployed |

|

| At a glance |

|

| Benefits for customers |

|

| Contact person | Thomas Burger |

SOFLEX Fertigungssteuerung GmbH

Manufacturing-control systems are the core expertise of SOFLEX. With its control technology, SOFLEX offers a complete portfolio of software products for entry into digital production control, from dynamic, detailed planning and job control all the way to fully automated workpiece and resource provision.

Automation example

| Project | Manufacturing-control system at Merz Maschinenfabrik |

| Project start | July 2014 |

| Project end | March 2015 (first stage) |

| Application | SOFLEX control system version PCS 4 |

| Company | Merz Maschinenfabrik GmbH |

| City, country | 72379 Hechingen, Germany |

| Industries | Machine building, single-cylinder circular knitting machines and automated circular knitting machines for the production of medical stockings and compression products |

| Products deployed |

Automated equipment:

Automated stand-alone machine:

|

| At a glance | Project started in June 2014:

Alteration in April 2017:

Alteration in October 2017:

Alteration in April 2018:

|

| Benefits for customer |

|

| Project link | |

| Contact persons | SOFLEX: Johannes Haar, Johannes Klaiber |

System suppliers

Indunorm Bewegungstechnik GmbH

Indunorm Bewegungstechnik is a supplier of linear motion technology and handling systems. Indumatik workpiece changers automatically load the machine tool with blanks and remove the finished parts, including during unattended shifts. Indunorm provides advisory services for the automation of existing and new equipment. It also both plans and produces tailored solutions as a single-source provider.

Automation example

| Project | Automation of a machining center with Batch Process Manager from HEIDENHAIN and Indumatik® Light 120 |

| Project start | January 2019 |

| Project end | June 2019 |

| Application | Production of single parts and small series |

| Company | DESMA Schuhmaschinen GmbH |

| City, country | 28832 Achim / Germany |

| Industry | Specialty machine manufacturer with in-house production |

| Products deployed |

|

| At a glance |

|

| Customer Advantages |

|

| Contact information | Indunorm Bewegungstechnik GmbH, Desma Schuhmaschinen GmbH, |

ZeroClamp GmbH

ZERO CLAMP develops and produces premium products for machining technology. Its applications are turning, milling, grinding, electrical discharge machining, and measurement. A recent addition to the ZERO CLAMP product portfolio is the Zerobot loading robot for the automation of production processes. Featuring a flexible handling system, the robot is made for automated parts production in small and medium-sized series starting at around five parts.

Automation example

|

Software suppliers

EVO Informationssysteme GmbH

The software manufacturer EVO Informationssysteme develops software solutions exclusively for the manufacturing industry. Its products include the PPS/ERP software EVOcompetition, the production data and documentation management system EVOjetstream, and the machine data acquisition software EVOperformance.

| Project | Digitalization and networked production |

| Application | EVO industrial software |

| Products deployed |

|

| At a glance |

|

| Benefits for customer |

|

| Project link | https://www.evo-solutions.com/en/evo-informationssysteme-gmbh |

| Contact person | EVO Informationssysteme, Mr. Jürgen Widmann |

EVOMECS GmbH

EVOMECS is an independent software provider for the manufacturing industry, adopting a cross-system and cross-machine approach. The EVOMECS software suite incorporates all relevent manufacturing elements for complete production process digitalization. Solutions from EVOMECS unlock important opportunities to improve efficiency while meaningfully enhancing workplace quality.

Automation example

| Project | Digitalization and complete linkage of in-house moldmaking to serial manufacturing |

| Project start | December 7, 2018 |

| Project end | June 30, 2023 |

| Applications |

|

| Company | ESCHA GmbH & Co. KG |

| City, Country | 58553 Halver / Germany |

| Industries | Industrial connectivity, in-house production equipment manufacturing |

Products deployed | Maschines:

Software applications:

|

At a glance | Project launch in December 2018:

Go-live of the MES system in February 2021:

Conventional deployment of MES throughout the moldmaking department starting in September 2021:

Preparatory work for tool management, MECS and job management starting in September 2022:

Go-live of tool management, MECS and job management in February 2023:

Process-data reporting launched in July 2023:

|

Benefits for customer |

|

Project link | https://www.evomecs.com/ |

| Contact persons | ESCHA: Benjamin Unruh, b.unruh@escha.net

EVOMECS: Benjamin Neubauer, benjamin.neubauer@evomecs.com |

Reniver

Automation example

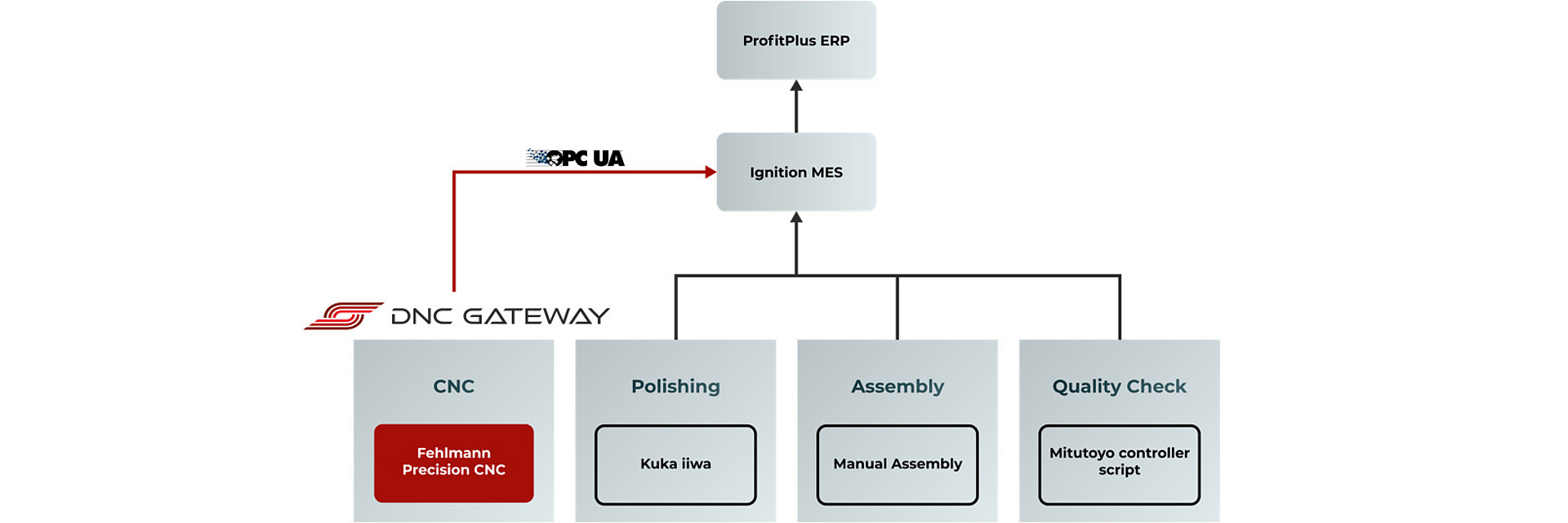

| Project | Connecting NC controls to an MES at Sirris |

| Project start | February 2024 |

| Project end | August 2024 |

| Application | Automation and data intelligence |

| Company | Sirris |

| City, country | Thor par Genk, Belgium |

| Industry | Discrete manufacturing |

| Products deployed |

|

| At a glance | Sirris wanted to create a Digital Product Passport (DPP) for each of its manufactured power banks. This required linking all machines, including the machining centers. By linking all machines, Sirris is able to reliably track manufacturing times, NC program run times, override settings, machine messages and other important data. Machine monitoring also provides benefits such as centralized alarm management, reduced downtime and the ability to determine key metrics regarding performance, availability and quality. |

| Benefits for customer | Thanks to the DNC Gateway from Reniver, all important CNC data can be linked directly to the MES. Sirris reaps the following benefits:

Seamless integration into the MES / ERP system: NC data can now be shared across the company, enabling improved synchronization among systems.

Lean manufacturing: Process and job planning can be optimized thanks to newly gained insights into actual machining times, machine statuses and machine downtime.

Less downtime: Staff can react faster to errors and reduce downtime thanks to centralized alarm management.

Optimized visibility: The precise tracking of production times and parameters for every product enables deep insight into production quality and improved process control. |

| Project link | www.reniver.eu/sirris-use-case/ |

| Contact person | Maarten Reekmans maarten.reekmans@reniver.eu +32 485 94 04 20 |

Service providers

RSConnect GmbH

RSConnect provides service solutions surrounding digital manufacturing. The company excels at digital retrofitting, predictive maintenance, energy data collection, StateMonitor setup and operation, and technology such as OPC UA, MQTT and web services. Its expertise includes the extraction, processing and transmission of data from HEIDENHAIN solutions and other systems to higher-level IT systems (MES or ERP). In this context, 5G wireless technology offers new potential for everything from efficient networking to digital business models. RSConnect is a technology partner for implementation, with an impressive range of services and many years of experience.

Sample application

| Project | Connecting machine data to StateMonitor: transparent processing of machine utilization and energy distribution data for a total of 18 systems with milling machines, lathes, and spraying machines from various manufacturers, as well as the required hardware modifications and parameter configurations |

| Project start | October 11, 2021 |

| Project end | October 15, 2021 |

| Application | Machining of components for industrial motor and automation technology |

| Company | LTN Servotechnik GmbH |

| City, country | 83624 Otterfing, Deutschland |

| Industry | Machine building industry, parts for various machines and systems |

| Products deployed |

|

| At a glance |

|

| Benefits for customer |

|

| Contact person | RSConnect |